LEAD LINED BOARDS - SHIELDING FOR LOWER ENERGY X-RAYS

It is very important to specify the correct thickness of lead for radiation shielding. A Radiation Protection Advisor or other shielding expert will usually do this, and when specifying the thickness of lead required where X-rays are being used for radiology and radiotherapy the RPA usually refers to the British Standard code numbers shown below.

We recommend the use of British Standard BS EN 12588 rolled sheet lead. Other globally recognised sheet lead standards can be supplied on request. If required we can provide clients with the services of totally independent professional RPAs as part of our scope of supply.

When specifying the thickness of lead required to shield a facility where X-rays are being used for radiology or radiotherapy the hospitals RPA usually uses the British Standard code number (see table below):

Although only milled lead manufactured to BS EN 12588 uses this thickness coding and colour system, it is always best to also refer to the British Standard when specifying sheet lead.

Although only milled lead manufactured to BS EN 12588 uses this thickness coding and colour system, it is always best to also refer to the British Standard when specifying sheet lead.

WALL SHIELDING

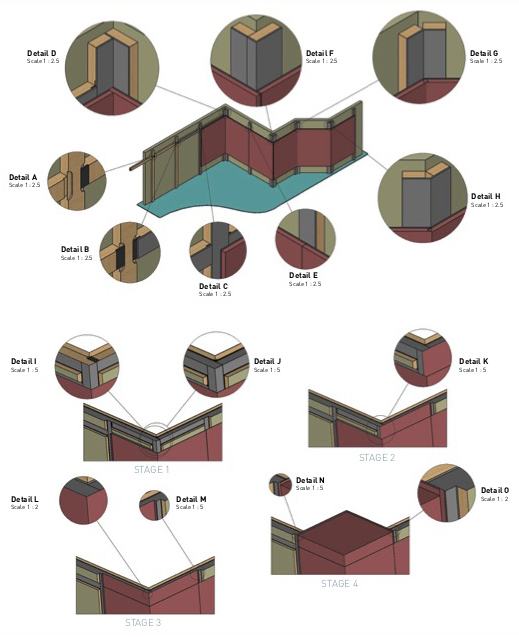

Calder’s standard panel sizes are 600 mm wide by 2400 mm in length. They are manufactured by bonding under pressure BS EN 12588 lead to plasterboard or plywood. During installation, the panels are mechanically fastened to either an existing wall or stud partition. When installing to an existing wall, a leaded batten is fastened to the wall at 600 mm centres, which the lead panels are then fixed to. On a stud partition a lead strip is bonded to all the vertical studs, before the panels are fixed. Leaded battens and lead strips are introduced to cover the butt joints of the panels, stopping leakage between the panel edges.

For shielding above 2400 mm in length, a horizontal leaded batten or lead strip is installed, which covers the joint between the panels. These are also used when fixings/penetrations are needed to be shielded. Calder’s lead lined panels can be supplied for install by others or we offer a guaranteed leak free, on-site installation carried out by our experienced installation technicians.

FLOORS AND CEILINGS

For shielding on floors and ceilings, panels are manufactured using plywood (normally 12mm) as this provides added strength. For ceiling installations, panel sizes are reduced so that the weight is easier to handle.

RADIATION SHIELDING:

DESCRIPTION

A laminated board comprising of lead sheet manufactured to BSEN 12588 pressure bonded using a pva adhesive to a gypsum plasterboard or plywood. Other substrates such as particle board or steel by special order.

APPLICATION

An easily installed and cost effective radiation shield used in x-ray suites, dental surgeries, CT scanner rooms and veterinary practices.

SHIELDING INTEGRITY

To ensure the elimination of shine paths and the integrity of the x-ray shield lead strips 50mm wide known as fillets and / or lead lined battens must be used where the edges of the boards meet.

AVAILABLE STANDARD SIZES

Width: Up to 600mm

Length: 2400mm and 3000mm

Lead thickness:

• 1.32mm (Code 3) weighing 14.97kg/m2

• 1.80mm (Code 4) weighing 20.41kg/m2

• 2.24mm (code 5) weighing 25.40kg/m2

• 2.65mm (code 6) weighing 30.05kg/m2

• 3.15mm (Code 7) weighing 35.72kg/m2

• 3.55mm (Code 8) weighing 40.26kg/m2

NB. The above weights do not include the weight of the substrate

The lead thickness required for shielding should be calculated by a fully qualified Radiation Protection Advisor. Due to excessive weight, Calder strongly recommend that Code 6 and above is bonded to plywood. Although 3m lengths are available if required, we suggest that for ease of handling the length is limited to a maximum of 2.4m.

NON STANDARD SIZES

These are available upon request.

INSTALLATION

The boards can be fitted to any timber or metal stud partition wall in conjunction with lead fillets.

If the boards are required to be fitted to a masonry wall lead faced battens are needed.

REQUEST A QUOTATION

Send all enquiries for supply and install or just supply only to sales@calderlead.co.uk